Why does a chain fly off a chainsaw or electric saw?

Owners of chainsaws from time to time face a common problem – a chain begins to fly off a chainsaw or electric saw. We will analyze why this happens later in this review.

There are only three main reasons why the chain flies:

- stretch;

- tire problems;

- asterisk problems.

Think about why this or that problem occurs:

If the chain is stretched, it begins to sag and slips off the tire

The reason is most likely the wear of the component itself. The chain has a limited lifespan and is the most rapidly worn out working element of a chainsaw or electric saw. The metal deforms under stress, not only becoming blunt, but also approx. 1 cm longer than with a new tool. The easiest way is to change the component, that is, buy and install a new chain.

You can read more about how the chain is tensioned and whether it is even possible to tension the chain at home in the test report.

If there are problems with the tire, they lie in the place of its attachment.

This reason is widespread: in the groove located between the outer plate mounted on the chain set and the inner plate located on the body of the benzo or electric saw. Normally the housing is screwed. This mount is called a motor node. The tire holder is covered with protective covers, as is the drive sprocket. When the mounting bolts loosen, the level of vibration of the tire increases, it begins to move.

In the event that there is nothing wrong with the tire, the tension is normal, as is the function of the tool itself. If the chain stretch is due to a loose bar, secure the bar and check how the chainsaw works.

Video – how to measure the length of a chainsaw tire:

Asterisk problem.

If the drive wheel is poorly secured, the chainsaw chain must also be tensioned, as sagging is unavoidable. Secure the tire sprocket by removing the engine guard, spark plugs and air filter. Instead of the spark plug, a plug is installed, the main task of which is to fix the piston. Then, using a special key or a universal key for an angle grinder, you can turn the clutch disc clockwise.

Make sure the plunger is in its extreme position – when you look into the hole for screwing in the candle, the plunger should be down.

After attaching the piston, you can proceed to tensioning the drive sprocket. Also, all the elements are assembled in reverse order.

Necessary devices and tools for pulling the chain on a chainsaw

In order to perform the tension correctly, you need to know some simple mechanisms and simple tools. With Stihl chainsaws, tensioning is very easy with the built-in chain tensioner. This method is as simple as possible, and such a stretch is performed very quickly. To tension or adjust chain slack, the manufacturer recommends:

- Use a wing nut to unscrew the sprocket cover.

- by turning the dial, determine the required length of chain and pull to the desired degree;

- The sprocket cover is closed again and the chain is securely fixed on the bar.

If it is not possible to tension the chainsaw chain with the built-in mechanism, I use the following tools (using the Sparky electric saw as an example):

- mill with a disc for metal;

- Allen key, diameter 5 mm;

- a piece of wire;

- wooden stick or strong splinter;

- flat screwdriver.

After turning off the saw, unscrew the hexagon screws, remove the housing cover, unscrew the clamping screw with a screwdriver and remove the threaded rod. The side of the screw adjacent to the saw body is ground with a disc. Then the saw is assembled in reverse order. A splitter is required to clean sawdust from the case.

How to properly tension a chainsaw chain:

When to shorten or stretch the chain

What to do if the chain needs to be shortened or stretched, links added or removed?

First, let’s find out in which cases it is necessary to shorten the chain, that is, remove links from it.

Chain shortening occurs:

- if there are not enough turns of the adjusting screw to tighten it;

- if a shorter than standard tire is fitted.

Accordingly, you can lengthen the chain if:

- a longer rod is installed on the saw;

- Some links are so worn that they have to be removed completely, which means that the chain is getting shorter and it has to be lengthened to its previous size.

Usually one or two links are removed. To make the chain smaller or larger, you need the following tools:

- a machine for removing rivets – a punch (a mechanical device working on the principle of a press and equipped with tips for extruding rivets and interchangeable grooves for different chain pitches);

- Riveting and rolling machine (designed for chains with a pitch of 1/4″ to 0.404″).

Video about the operating principle of the Oregon riveter:

Video about the work of the Oregon riveting machine

How to determine the size and pitch of the chain

There are three important parameters for chainsaw chains and chainsaws:

- step;

- length;

- thickness.

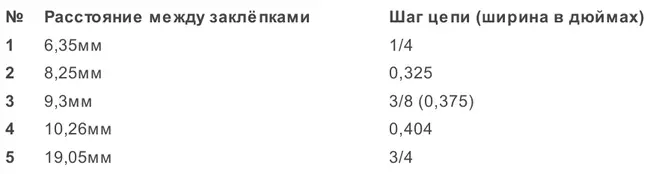

Table 1 shows the rivet spacing that allows the owner to correctly determine the chain pitch. In addition, the instructions for the original electric saw or chainsaw will definitely indicate the pitch, length and number of links.

Table 1.

The total length of the chain depends on the exact number of teeth on the inside. You need to count the number of drive links, this is the length of the chain.

Example: For a 40 cm bar you can use chains with a different number of teeth, e.g. 57, 56 or 55. The number of teeth depends on the model.

It would be a mistake to assume that all hoops with a length of 40 cm can be worn with the same chains.

Video – how to tension a chain on a Stihl chainsaw:

It is also important to know the thickness of the shaft (drive link). The shank holds the chain to the bar. To understand how the thickness of this part should be measured, see Table 2.

Table 2. Shank thickness.

For non-professional chainsaws, a chain pitch of 0.325 inch is most common. These chains are ideal for chainsaws up to 2500 watts. It is better not to choose a chain yourself, but with the help of a seller or a specialist who works with accessories for chainsaws and electric saws.

Video with tips – how to choose a chain for a chainsaw:

How do you rivet a chain?

A rivet is the joining of a broken chain or the creation of a solid chain after the addition of links, and this term is also used to refer to the process of shortening a chain. For riveting, it is recommended to use special riveting machines and machines.

Video on riveting a chainsaw chain with your own hands:

The following video shows the chain riveting process on the machine:

Chain tension principle

The principle of chain tension is as follows:

- the standard wrench supplied with the chainsaw loosens the nuts on the cover;

- then the screwdriver is inserted into a special groove, rotary movements are performed and the chain is tightened;

- the key should be turned slowly and carefully – after a couple of turns, the degree of tension is controlled manually, then several turns are made again if necessary;

- When the chain is sufficiently tensioned, you need to attach the cover.

To work with hard materials, specialists use carbide chains made of pobedite material. They are not made entirely of pobedite, but are soldered from this material. Mainly used for ripping concrete, aerated concrete and especially hardwoods.

The carbide chain has the right strength, it dulls a lot less, but costs 3-4 more than the standard chain. Sharpening a winning chain at home is not possible, this requires special equipment.

How to check the chain saw tension

To check whether the chain is correctly tensioned and needs to be retensioned, pay attention to the following displays:

- if the tension is correct, the sawing quality is good, the bar sinks quickly into the material, cuts easily and without getting stuck in the wood;

- the tire does not heat up during operation;

- Sawing produces both small and large chips.

The chain must be tightened if:

- the tire gets very hot;

- the sawing quality is reduced, the cutting edge is uneven;

- increased fuel and oil consumption;

- only small chips are formed.

Tips for further operation of the saw after tensioning the chain

To make the chain last longer and not sag, follow these recommendations from experienced owners:

- keep an eye on the constant lubrication of the tire;

- Properly mix fuel and oil for refueling a chainsaw;

- When sawing, hold the chainsaw as straight as possible without tilting too much to the right or left;

- use chains with the correct pitch from reputable manufacturers;

- Replace worn parts in time.

Videos

Reviews

Vladislav, Bucha:

“I would like to advise all inexperienced chainsaw owners: No matter what kind of saw you have, you must tension the chain in good time! If it sags a lot, or vice versa, it will be stretched a lot, both options are bad. In general, I advise you to tighten it after about 3-5 cubes of firewood. And get saws that have a tensioner option. For example, almost all Husqvarns, including the Patriots, have such a function.

Also be careful with the chain so that it doesn’t fly away – it’s very dangerous if it jumps off right when you’re sawing! You can hurt yourself badly. All great work!”